Composite Materials Engineering Facilities & Equipment

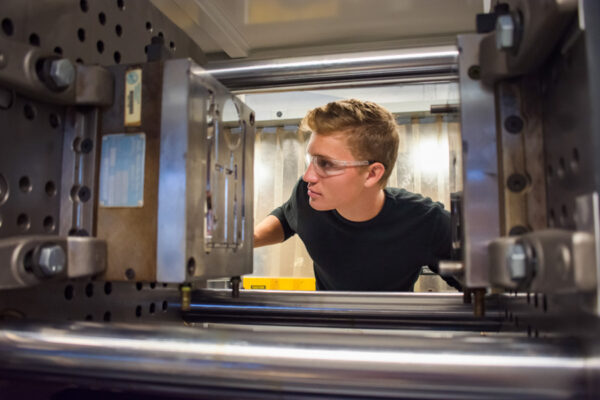

Composite Materials Engineering (CME) students use high-tech and continuously updated laboratories and equipment to analyze, design, manufacture, and test composite materials and structures.

Ready to get started? Review the Lab Safety and Hazardous Materials.

- Sartorius Analytical Balance

- Sartorius Milligram Balance

- Sartorius YDK 01 Kits

- Mettler M3 Weighing Scale

Computer Hardware: 40 Dell Computer Stations

Software

- SolidWorks

- ProModel Simulation Software

- Autodesk Moldflow

- Environmental and Humidity Chamber

- QUV Accelerated Weathering Tester

- Blue M Controlled Relative Humidity Chamber

- Heat Distortion Unit

- Flexural Creep Unit

- Taber Standard Abrasion Tester

Pultrusion: Mec-Pro Manufacturing Inc. Model 5570

Filament Winding

- Durawinder Cobra Model 11A

- McClean Anderson 6″ dia, 120″ length

Extrusion and Mixing: Brabender (single screw, twin screw, mixing bowl)

Injection Molding: Milacron Magna T, 55 Ton 3.7 oz

Press Molding

- CARVER MONARCH Series Hydraulic Compression Press to 50 tons & 780 ◦F; 18″ x 18″ Platen

- Hull Press to 15 tons & 400 ◦F; 12″ x 14″ Platen

- Fuchs Press to 15 tons & 325 ◦F; 28″ x 28″ Platen

- Carter (manual) Press to 12 tons & 400 ◦F; 7″ x 10″ Platen

- Carver (manual) Press to 25 tons & 400 ◦F; 9″ x 9″ Platen

Ultrasonic Welding: Branson Intelligent Actuator 2000 AED

Ovens and Furnaces

- Blue M Oven to 400 ◦F; 3.5′ x 3′ x 2′

- Baxter Ovens to 500 ◦F; 1.5′ x 1.5′ 1.5′

- High Temperature Furnace to 2,500 ◦F; 13″ x 13″ x 8″

- Autoclave: 2′ Dia. X 3.5′ Length

Ultraviolet Curing Chamber

3D Printing & Scanner

- Markforged Mark Two

- Seemecnc Rostock Max v3.2

- Stratasys Dimension BST 768

- Afinia 3D scanner

- Instron Testing System Model 68TM50

- Instron Model 68FM, Capacity 300 kN

- Instron Model 8801 Axial Servo-hydraulic Testing System

- Instron Model 5982 Material Testing System, Capacity 100 kN

- Instron Model 9050 Pendulum Impact Tester for Izod/Charpy Impact

- Low Velocity Impact Tower

- Sample Notcher

- Leco Rockwell Hardness Tester Model R-260

- Mitutoyo Micro-Vicker Hardness Tester MVK-G2

- Reactive Floor System

- FEI Quanta 250 Scanning Electron Microscope

- Hummer VI-A Anatech Sputter Coater

- Nikon Stereozoom Microscope

- Nikon Labophot – 2 Microscope

- Nikon Alpha Photo – 2 Microscopes

- Global Lab Image Processing Software

- Image – Pro and Materials Software

- Buehler Isomet Low Speed Saw

- Buehler Metaserv Grinder – Polisher

- Teledyne Powder/Solid Mixer

- Metal Shop

- Wood Shop

- Hurco VMI 3Axis CNC Machine

- Welding Station (to include Tig/Mig/Plasma)

- TA Instrument Thermo-Mechanical Analyzer

- TA Instrument Thermo-Gravimetric Analyzer

- TA Instrument Dynamic Mechanical Analyzer

- TA Instrument Modulated Differential Scanning Calorimeter

- TA Instrument AR 2000 rheometer

- TA Instrument DHR-2 rheometer

- Instron MF20 Melt Flow Tester

- Brookfield Rotational Viscometers

- Armfield Heat Convection Unit

- Armfield Heat Conduction Unit

- Armfield Drag Coefficient Apparatus

Take a Virtual Tour

Explore what the facilities and equipment are available to students enrolled in the program and learn more about studying Composite Materials at Winona State.